Sustainability

Although the Pevensey Bay Sea Defence project exists to maintain a 9km long shingle

Although the Pevensey Bay Sea Defence project exists to maintain a 9km long shingle  embankment, it is classified as an environmental scheme, and as such has always had environmental awareness at the forefront of all activities. Very early in the 25 year project, we recognised that the best way to maintain the beach, reduce risk of further erosion, and protect neighbouring properties was to set out a sustainable strategy for construction and maintenance of the embankment. Sustaining the beach in order to protect local communities and the surrounding environment inherently embraces the concept of sustainable development. However, it has only been more recently that the concept of overall sustainability has begun to replace a purely environmental view.

embankment, it is classified as an environmental scheme, and as such has always had environmental awareness at the forefront of all activities. Very early in the 25 year project, we recognised that the best way to maintain the beach, reduce risk of further erosion, and protect neighbouring properties was to set out a sustainable strategy for construction and maintenance of the embankment. Sustaining the beach in order to protect local communities and the surrounding environment inherently embraces the concept of sustainable development. However, it has only been more recently that the concept of overall sustainability has begun to replace a purely environmental view.

The project has had an Environmental Management Plan in place since it started in 2000, but it is now time for us to formalise a sustainability policy by means of a Sustainability Action Plan. Along with many others, we have used the definition of ‘sustainable development’ to be that included in the 1987 Bruntland Report as;

‘development that meets the needs of the present without compromising the ability of future generations to meet their own needs’.

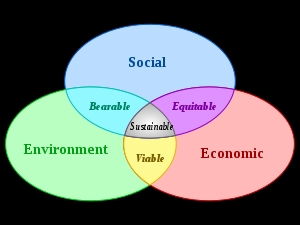

In order to present a balanced approach, the plan considers equally the “three pillars" of sustainability;

- The environment

- Social or community needs, and

- Economic viability

Now into our twelfth year, we have been able to apply innovative techniques to management of the defences and in doing so helped develop evolution of best practice. Lessons learnt and are now being used to good advantage on site, and are starting to be used elsewhere. Over the remaining years, we recognise the need to continue to respond to wider sustainability challenges and opportunities that arise. To do so requires a fully integrated approach to managing social, environmental, community, ethical and broader economic factors. Therefore this plan not only confirms our commitment to sustainability but also outlines a series of targets and actions under each of the three key sustainability strands. In its preparation it has been reviewed and aligned to the economic, social and environmental commitments of our shareholders and our client, the Environment Agency. It remains a living document and hence must respond to changes that occur, both in our own operations and in the needs of our stakeholder’s organisations, each of which has a special interest in the project area.

Whilst we seek the views of stakeholders on a regular basis, we welcome equally those of individuals and other groups. There are several ways for individuals or organisations to voice their views;

- A copy of our Sustainability Questionnaire can be found here.

- Commment via the feedback form, which is here, to record general remarks, or make specific points.

- Via email to pcdl@pevensey-bay.co.uk

A copy of the current Sustainability Action Plan can be downloaded here.